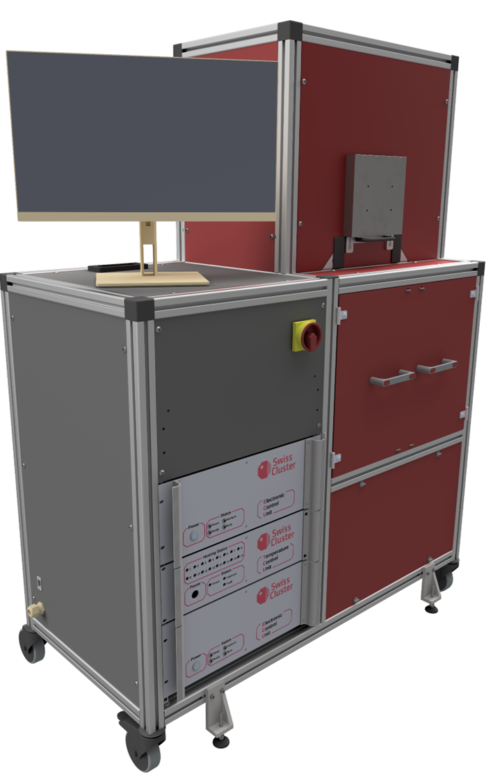

TFS 200

TFS 200 is the most flexible ALD research platform ever designed for academic research and corporate R&D. Beneq TFS 200 has specifically been designed to minimise any cross contamination that could happen in a multi-user research environment. The large number of available options and upgrades means that your Beneq TFS 200 will grow with you to meet even the most demanding research requirements.