GASEX MODULAR

The ARCoptix GASEX MODULAR is a fully configurable solution for gas spectroscopy applications. Besides the GASEX OEM module, the system can offer a large variety of standard components and accessories as requested by the end user application. Typical examples of accessories are heated sample lines, single board computers (SBC) for on-board processing, membrane gas pumps and so on. The GASEX MODULAR is available in a 19″ rackable chassis (4U) for smooth integration in a more complex system.

Innova 1314i

Advanced Energy’s Innova 1314i is a highly accurate, reliable, and stable quantitative gas monitor. Its measurement principle is based on the photoacoustic detection method. Extremely versatile by design, the 1314i can measure at trace levels almost any gas that absorbs infrared light.

- Multi-gas monitoring of up to five different gases (+ water vapor) can be measured with excellent sensitivity and accuracy

- Suited for permanent monitoring tasks at low O&M costs

- Highest stability (low drift) makes calibration only necessary one to two times per year

Innova 1403

The Advanced Energy Innova 1403 is a reliable, easy-to-use multipoint sampler and doser. It combines with the Innova 1512 photoacoustic gas monitor and a controlling computer featuring the Innova 7650 basic ventilation software to offer numerous monitoring capabilities.

- Increase area monitoring capabilities of the gas monitor by collecting air samples through tubing from up to six sampling points

- Full remote control from a PC with Innova ventilation software

- Factory calibrated dosing system includes automatic calculation of tracer-gas delivered to the dosing location

- Self-test function for verification of the unit’s operation

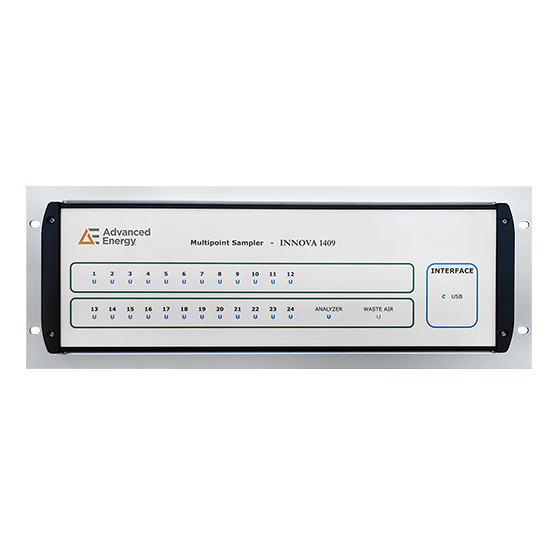

Innova 1409

The Advanced Energy Innova 1409 is a reliable, easy-to-use multipoint sampler for gas sampling of up to 24 different locations. The Innova 1409 is designed to be remotely controlled from a PC using a USB interface in conjunction with an Innova Photoacoustic Gas Monitor to provide a flexible, sensitive, and accurate monitoring system.

- In conjunction with an Innova gas monitor, measure concentrations of up to five gases, water vapor, and air pressure in each sample

- Full remote control from a PC with Innova ventilation software

- Remotely control the instrument by using an Innova photoacoustic gas monitor or a PC

Innova 1512

Advanced Energy’s Innova 1512 is based on the photoacoustic infrared spectroscopy and delivers superior sensitivity in a very compact form factor. Extremely versatile by design, the 1512 is capable of measuring almost any gas that absorbs infrared light.

- Leverages the unique strengths of the photoacoustic sensor technique

- User-friendly, stable, reliable, and highly accurate

- Extremely low-volume flushing possible